The next major market for nonwoven fabrics is likely to be as the preferred filter media carrier materials for a fast-rising and as yet little-known technology called Direct Air Capture (DAC).

Carbon capture systems are already widely employed at the source of industrial complexes where major CO2 emissions are generated – refineries and hydrogen, cement, steel, aluminum, paper plants etc.

The developers of DAC systems, however, are aiming for something much more ambitious – in short, removing the existing CO2 from the atmosphere.

As unlikely as this proposition may sound, it’s now being taken very seriously in the USA and in August the US Department of Energy (DOE) announced $1.2 billion in funding for the development of two commercial-scale DAC facilities in Louisiana and Texas.

DAC Hubs

The two projects announced by the DOE represent the initial selections from President Biden’s DAC Hubs programme, kickstarting a nationwide network of large-scale carbon removal sites planned to address legacy CO2 pollution and complement rapid emissions reductions.

Together, the two projects are expected to remove more than 2 million metric tons of CO2 each year from the atmosphere once fully scaled – an amount equivalent to the annual emissions from roughly 445,000 cars – while also creating 4,800 well-paid jobs in Louisiana and Texas.

“Cutting back on our carbon emissions alone won’t reverse the growing impacts of climate change – we also need to remove the CO2 that we’ve already put into the atmosphere which nearly every climate model makes clear is essential to achieving a net-zero global economy by 2050”, said US Secretary of Energy Jennifer M. Granholm. “With this once-in-a-generation investment made possible by President Biden’s Investing in America agenda, the DOE is laying the foundation for a DAC industry crucial to tackling climate change –transforming local economies and delivering healthier communities along the way.”

The DOE estimates that reaching President Biden’s plan for a net-zero emissions economy will require between 400 million and 1.8 billion metric tons of CO2 to be removed from the atmosphere and captured from emissions sources annually by 2050.

Metal Organic Frameworks (MOFs)

There are a number of different Direct Air Capture (DAC) technologies for filtering CO2 from the air by either absorption or adsorption employing nonwoven carrier materials, using common chemicals which are already in use in other applications – notably water and gas filtration. They include amine-functionalised sorbents and MOFs – metal organic frameworks – which now show the most promise for the future.

MOFs are materials composed of metal ions and organic ligands that form a three-dimensional structure with a high surface area and well-defined pore size and porosity. These properties make MOFs ideal for gas storage and separation, including carbon capture.

As a leader in nonwoven filter media, for example, 3M has recently partnered with a US company called Svante Technologies to mass produce MOF-coated filter media.

Ray Eby, president of 3M’s Personal Safety Division, said that the company is eager to take on the challenge of scaling the production and supply of carbon removal materials over the next decade – in a similar way to how it managed to triple the production of nonwoven-based N95 respirators in response to the Covid-19 pandemic.

“Our deep expertise in filtration technology, extensive global R&D community and unwavering commitment to creating world-changing solutions give us the confidence to scale these carbon-adsorbing solutions with the necessary speed to combat climate change”, Eby said.

Benefits

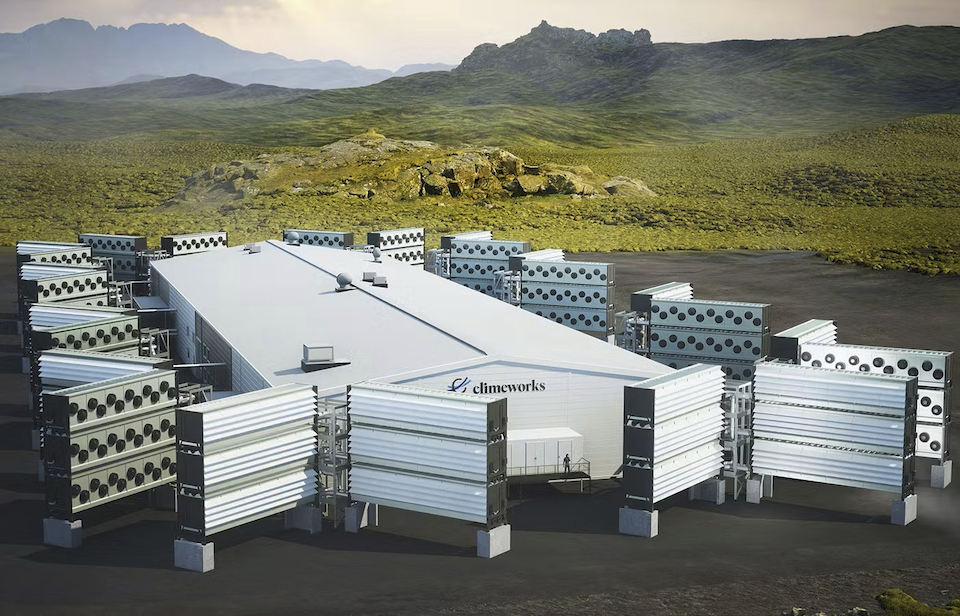

The companies with the most developed Direct Air Capture technologies today include Climeworks, headquartered in Zurich, Switzerland, Canada’s Carbon Engineering and Global Thermostat, of Brighton, Colorado. All are involved in the US DAC Hubs project.

The key benefits of DAC according to Climeworks, are that it is location-independent, highly scalable and measurable and enables efficient land usage.

CO2 is in the air at the same concentration everywhere in the world, which means that DAC plants can be located anywhere as they do not need to be attached to an emissions source. They are only required to be placed near a renewable energy source and in a place where CO2 can be stored.

Climeworks plants are based on a modular technology design, making them highly scalable and they require less land than other techniques. The planting of trees is the most obvious and natural way of absorbing carbon, but on a land area of 0.42 acres, the Climeworks Orca plant already established in Iceland can remove 4,000 tons of CO2 from the air every year – which is almost 1,000 times more effective than trees. The same land would host around 220 trees with an estimated capacity of 22kg each – only 4.62 tons of CO2 per year.

Continuous process

All Direct Air Capture technologies so far, however, are based on batch processes in which the filter media has to be replaced once fully loaded.

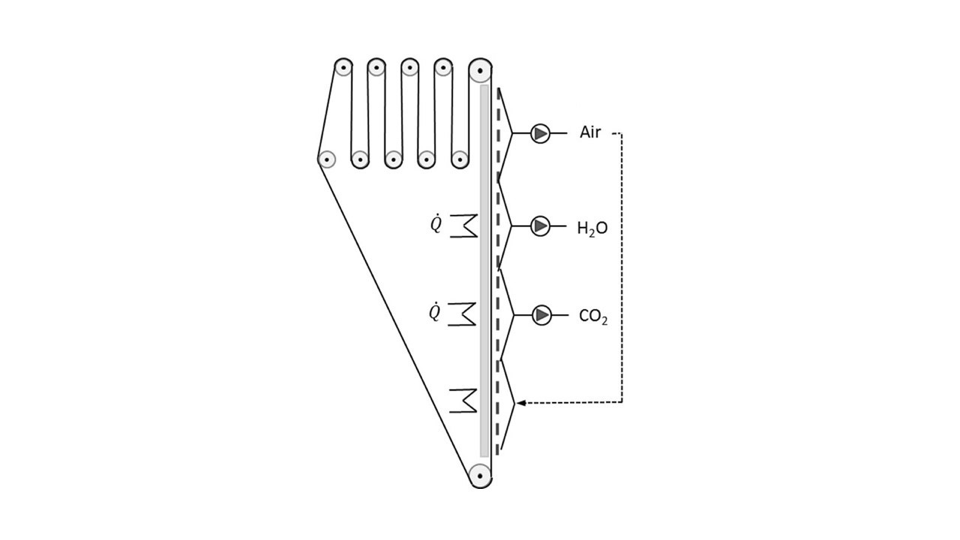

In the German Cora Project, work is consequently ongoing on the development of a fully scalable and energy-efficient continuously running process.

The project brings together ZSW, the Centre for Solar Energy and Hydrogen Research, and the German Institutes of Textile and Fabric Research (DITF), with industrial partners including Mercedes.

DITF has developed the special nonwovens for the efficient absorption and desorption of CO2 based on its HiperCell cellulosic fibres process. The fibres are chemically modified with amines to ensure the temporary binding of the CO2 to the filter material. The advantage of using cellulose nonwovens is in their open, air-permeable structure – not only do they allow a high air throughput, but they also have a large specific surface area, which is advantageous for binding the largest possible volumes of CO2.

These nonwovens run through a special continuous running belt system which is currently being perfected, with a view to scale-up, drawing on the technology and process know-how of Mercedes and other industrial partners.

Fig Leaf

Direct Air Capture is not, however, without its critics and worries have been expressed that it potentially creates a fig leaf for the fossil fuel industry to keep on drilling for oil. Sceptics have also suggested that the money being invested in it could be much better spent on actual climate solutions that would be cutting emissions from the start.

Whether that’s the case or not, there is little doubt, that given the major support it already has, DAC is poised to rapidly assume a major part in the fight against climate change, with nonwoven fabrics once again playing a crucial role.